To know about particular products information

Fill This Form to contact us, our team will get in touch within 24 hours.

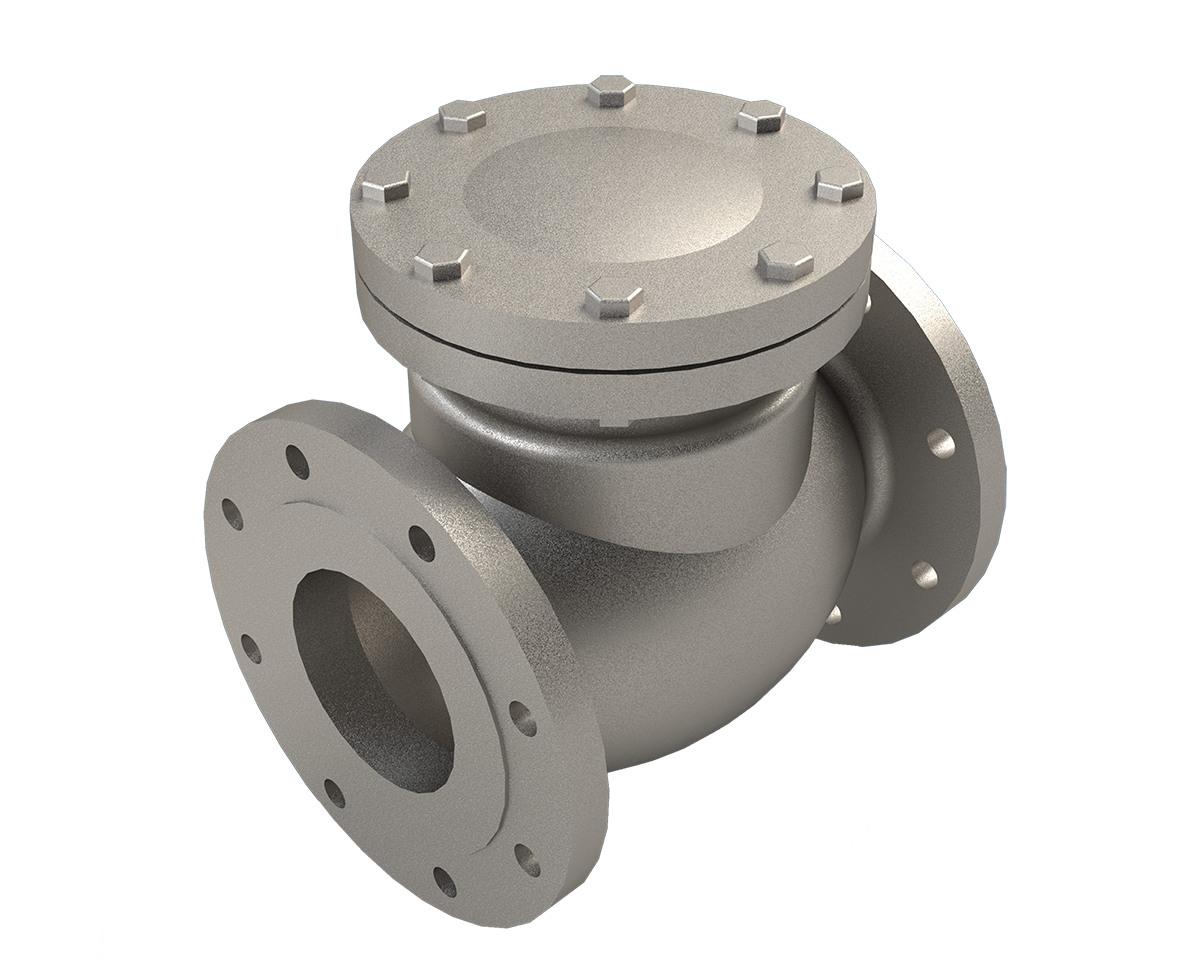

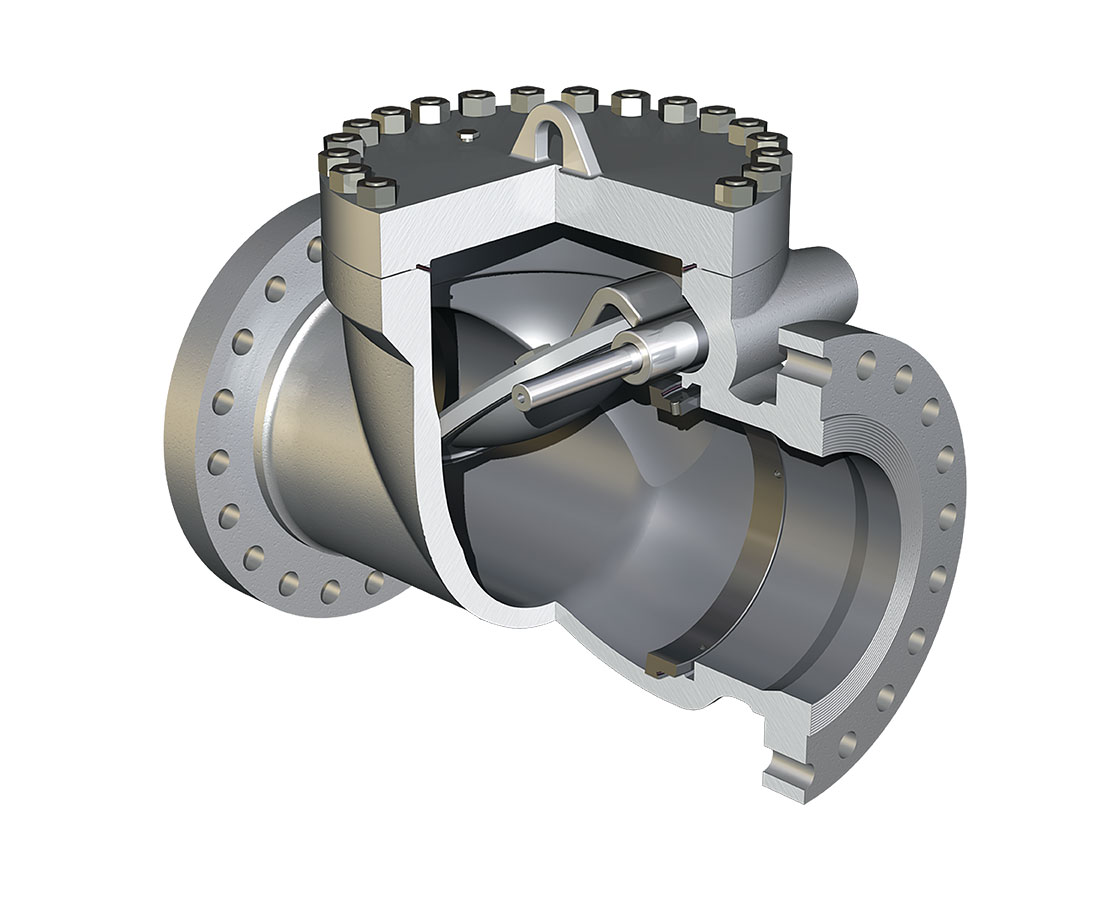

The check valve is the most commonly used valve in residential and commercial complexes. Anvil Metal Corporation offers world-class varieties of check valves that are perfect for different settings. We are a global player whose name is a synonym for quality in the check valves manufacturers industry. We like to introduce ourselves as innovators with traditional roots who create check valves that perform the traditional function in a smarter way. Our designers and machinists are constantly looking for technologies and innovations that can help us manufacture the best quality valves.

50NB to 600NB

Up to 6000 psi

Up to 350° F

316 SS

Duolok, Griplok and Unilok tube ends, male and female NPT and BSPT

Check valves are self-activating safety valves that permit gases and liquids to flow in only one direction. The purpose of a check valve is to prevent process flow from reversing in the system which could damage equipment or upset the process. They are classified as one-way directional valves. Check valves are commonly found protecting pumps in liquid applications or compressors in gas systems where backflow could cause the pump or compressor to shut down. They are also applied in process systems that have varying pressures, which must be kept separate. They do not need an outside power supply to operate since they use the pressure drop created by the media flow.

WhatsApp us